Brand Name: HX

Model Number: SD tunnel series

Place of Origin: Tianjin, China (Mainland)

Condition: New

Type: Tunnel Freezer

Voltage: 220V/380V AC

Power(W): 7.5kW~55kW

Dimension(L*W*H): 6500*3400*2850mm~25000*6000*2850mm

Weight: 8~15tons

Certification: ISO,CE

Warranty: 1 Year

After-sales Service Provided: Engineers available to service machinery overseas

Product name: Commercial Meat IQF Tunnel Blast Freezer Machine

Production (kg/h): 100~3000kgs/h

Freezing Temp (℃): -35

Evaporation Temp (℃): -42

Feeding Temp (℃): 25 or as demands

Out-feeding Temp (℃): -18 or as demands

Cooling Capacity (kW): 40~290kW

Defrosting Times: 1time/24hours

Material: Stainless steel sheet

Refrigerant: R404A, R717

Commercial Meat IQF Tunnel Blast Freezer Machine

IQF Tunnel Freezer Introduction

Iqf tunnel freezer machine is one of the most commonly used blast freeze, the application is very wide. Commonly used in dumplings, glutinous rice balls, steamed bag and so on art factitious product, but also can be used for aquatic meat product, poultry products and fruits, vegetable for processing.

SD series net belt tunnel quick freezer uses a stainless steel net belt as the conveyor, prepared foods put in containers or put on the stainless steel net belt directly and frozen by cooling air from bottom to top.

IQF Tunnel Freezer Picture

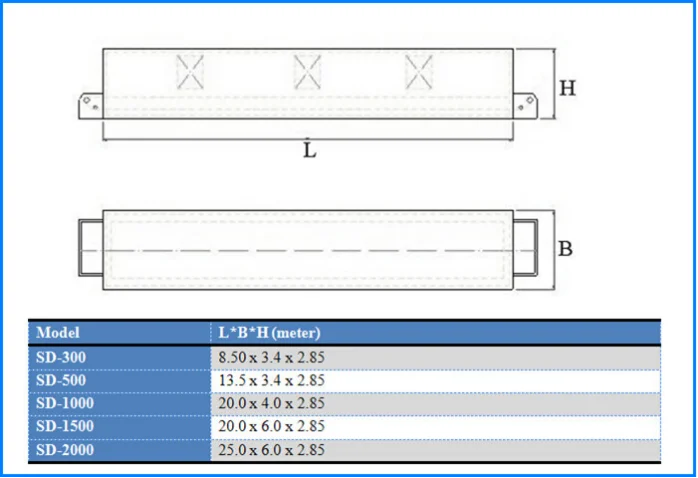

Technical Parameter

Model |

SD-300 |

SD-500 |

SD-1000 |

SD-1500 |

SD-2000 |

Production (kg/h) |

300 |

500 |

1000 |

1500 |

2000 |

Freezing Temp (℃) |

-35 |

-35 |

-35 |

-35 |

-35 |

Evaporation Temp (℃) |

-42 |

-42 |

-42 |

-42 |

-42 |

Feeding Temp (℃) |

25 |

25 |

25 |

25 |

25 |

Out-feeding Temp (℃) |

-18 |

-18 |

-18 |

-18 |

-18 |

Cooling Capacity (kW) |

48 |

75 |

150 |

218 |

290 |

Refrigerant |

R717,R404A |

R717, R404A |

R717, R404A |

R717, R404A |

R717, R404A |

Defrosting Method |

Water, Hot ammonia |

||||

Defrosting Times |

1time/24hours |

||||

Products |

Standard products like dumplings, spring roll, the freezing time is about 30min, and the put density is 5.8kg /m2. Other food need adjusted depend on above. |

||||

Power(KW) |

7.5 |

10.5 |

38 |

45 |

55 |

Dimensions (L×B×H) m |

8.5*3.4*2.85 |

13.5*3.4*2.85 |

20.0*4.0*2.85 |

20.0*6.0*2.85 |

26.0*6.0*2.85 |

Freezer Components

Item |

Contents |

Supporting frame structure |

SUS304 stainless steel bracket and fenders, mesh belt holder with a food-grade polymer polyethylene plastic, wear-resistant, long life. Bracket using a 75mm × 45mm × 1.5mm stainless steel square tube. |

Insulation library body |

SUS304-sided stainless steel, of a thickness of 0.6mm, polyurethane filling foam, density 42 kg / m 3, the insulation thickness 120mm. |

Fan |

Efficient low-power axial fan, are made the cold storage dedicated three anti Motor, Blade hairdryer and bracket are made of stainless steel. |

Evaporator |

Aluminum tubes and aluminum fins evaporation tube φ25mm × 2.2mm. |

Conveyor Belt |

Encrypt SUS304 stainless steel spring steel wire mesh belt, stainless steel chain, chain slice thickness of 2.5mm, |

Transmission system |

Cycloid reducer, a drive unit. |

Control cabinet |

SUS304 stainless steel cabinet, with voltage, current meter, thermometer and digital display, inverter control, the main components Schneider brand. |

Freezer Advantages

1. High speed, about 5-10 minutes quick freezing, saves time cost.

2. Environmental to earth and human. It is the popular trend.

3. Low noise, like a home refrigerator.

4. Little moisture loss, improve product quality and worth.

5. Low power consumption, 3 hours consume about 1 KWH.

6. Low operating cost, 1 ton liquid nitrogen can freeze about 3 tons product.

7. Little damage to cell tissue, as the speed is quick, so it has little damage to cell tissue.

8. Easy to operate, any people can operate.

9. Low labor cost, one people can finish all the freezing work.

Freezer Application

IQF Tunnel Freezer Details:

IQF Tunnel Freezer Structure